Wooden Laminate

STEP 1

Put the unopened packs into

the room to acclimatise for 48 hours. The flooring is thin enough to fit

under most doors, but to check place a board on the underlay next to the

door. If it won’t open, remove from its hinges and plane the bottom

edge.

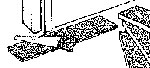

The

new floor also needs to fit under the architrave. If necessary, saw the

bottom of the architrave so that a board plus underlay can slide

underneath. Skirting boards do not need to be removed

to fit flooring as the gaps around the edge of the room can be hidden by

a matching self-adhesive cover strip or beading. However, if you wish to

remove skirting boards to replace them over the gaps later, this should

be done now.

The

new floor also needs to fit under the architrave. If necessary, saw the

bottom of the architrave so that a board plus underlay can slide

underneath. Skirting boards do not need to be removed

to fit flooring as the gaps around the edge of the room can be hidden by

a matching self-adhesive cover strip or beading. However, if you wish to

remove skirting boards to replace them over the gaps later, this should

be done now.

STEP 2

Look to see which direction

the light falls into the room. If possible, lay the boards so that the

sunlight falls along their length.Polythene underlay must be used under

the foam underlay on concrete floors or wherever there is any chance of

moisture passing from the sub floor to the boards. Overlap sheets by at

least 20cm (8") and take the edges up the wall by 2.5cm (1").

Any excess can be cut off later.

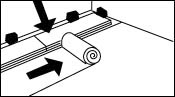

Foam

underlay helps to reduce the sound of footsteps and levels slight

unevenness. Roll the foam in the same direction and the new boards will

be laid, a length at a time, making sure that the polythene flap is

overlapped by the foam at the joints. Measure the width of the room and

work out how many rows of boards the floor will contain. If the last row

is less than 8cm (3") wide, begin by cutting the first row of

boards so that they are approximately the same width as the last row.

Foam

underlay helps to reduce the sound of footsteps and levels slight

unevenness. Roll the foam in the same direction and the new boards will

be laid, a length at a time, making sure that the polythene flap is

overlapped by the foam at the joints. Measure the width of the room and

work out how many rows of boards the floor will contain. If the last row

is less than 8cm (3") wide, begin by cutting the first row of

boards so that they are approximately the same width as the last row.

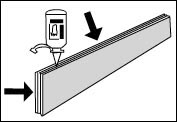

Lay the first row of boards,

from left to right, without gluing, with the groove facing the wall,

leaving an expansion gap of 9mm around all edges (a pair of spacers). As

all walls are slightly uneven and the boards must be kept straight,

adjust the spacers to accommodate small differences in width. If your

walls are very uneven you will need to cut the boards to follow the

wall. Mark where to cut the boards by holding a pencil against a spacer

and sliding it along the wall.

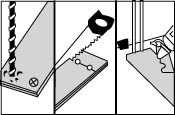

To

avoid damaging the surface, if using a handsaw the top of the board

should face upwards when cutting, if using a jigsaw the bottom of the

board should face upwards. Insert spacers every 40cm (16") between

the wall and boards and at both ends of each row. To cut the board at

the end of the row place it so that its tongue is touching the last

board laid, mark the cutting line and saw.

To

avoid damaging the surface, if using a handsaw the top of the board

should face upwards when cutting, if using a jigsaw the bottom of the

board should face upwards. Insert spacers every 40cm (16") between

the wall and boards and at both ends of each row. To cut the board at

the end of the row place it so that its tongue is touching the last

board laid, mark the cutting line and saw.

Start the second row with

the piece of board left from the first row. If it is shorter than 20cm

(8") cut a new board. Lay the second and third rows without gluing

and adjust as necessary so that the rows are straight. If all the joints

meet properly then the floor has been laid straight. Boards should

always be laid so that there is at least 20cm (8") between joints

to maintain the strength of the floor.

STEP 3

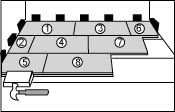

When gluing, the first three

rows are laid at the same time, as it is easier to keep the rows

straight and quicker to lay your floor. The boards are laid in an

overlapping pattern in the order shown in the diagram below. For boards

in the first row, apply glue to the upper edge of the end groove only.

Place the hitting block over the tongue and hammer to push the panels

together. Never hit the tongue or groove directly. Immediately remove

glue from the face of the boards with a cloth.

For

boards in the second and third rows glue the upper edge of the grooves

along both sides and ends of the boards. Carefully tap the end then side

joints together using the hitting block. Use the crowbar to tighten the

last board in each row and finish with spacers. Lay the rest of the

floor a row at a time.

For

boards in the second and third rows glue the upper edge of the grooves

along both sides and ends of the boards. Carefully tap the end then side

joints together using the hitting block. Use the crowbar to tighten the

last board in each row and finish with spacers. Lay the rest of the

floor a row at a time.

The last row: The last row

of boards will normally need to be cut down their length. Mark the

cutting line by placing a board directly on top of the last row laid,

groove facing you, with an off cut on top, tongue against the wall.

STEP 4

To fit around pipes: mark

the position of the pipe on the board, allowing for the expansion gap.

Measure the width of the pipe and drill or chisel a hole in the board

(use a drill bit 18mm (3¼4") larger than the pipe to allow for the

expansion gap). Cut a section from the board, lay the board around the

pipe and glue back the sawn piece.

Finishing:

Remove all traces of dust from the floor. To cover the gap either peel

the backing from the cover strips and attach, replace the skirting

boards, ensuring that the floor can move freely underneath, or use a

timber beading or moulding of your choice, fixing it to the skirting to

allow the floor to move freely.

Finishing:

Remove all traces of dust from the floor. To cover the gap either peel

the backing from the cover strips and attach, replace the skirting

boards, ensuring that the floor can move freely underneath, or use a

timber beading or moulding of your choice, fixing it to the skirting to

allow the floor to move freely.

Where the floor meets carpet

or linoleum use a threshold to bridge the height difference.

STEP

5

STEP

5

Maintaining your floor:

Flooring is a durable smooth surface and so needs a minimum of

maintenance. To keep your floor looking its best:

DO